Overview

In my opinion, the invention and widespread implementation of the stepper motor is the best thing that has ever happened to the modern-age DIYer. Replacing expensive closed-loop servo motors with stepper motors drastically reduced the cost of buying many of the CNC machines that are present in an industrial shop, like CNC mills and laser/plasma cutters. This allowed DIYers to bring many of these technologies to their home shop. To be upfront, servo motors are still the leaders of accuracy and precision, but for FFF 3D printing the stepper motor is more than sufficient for churning out quality prints on your custom 3D printer.

A Precise Step

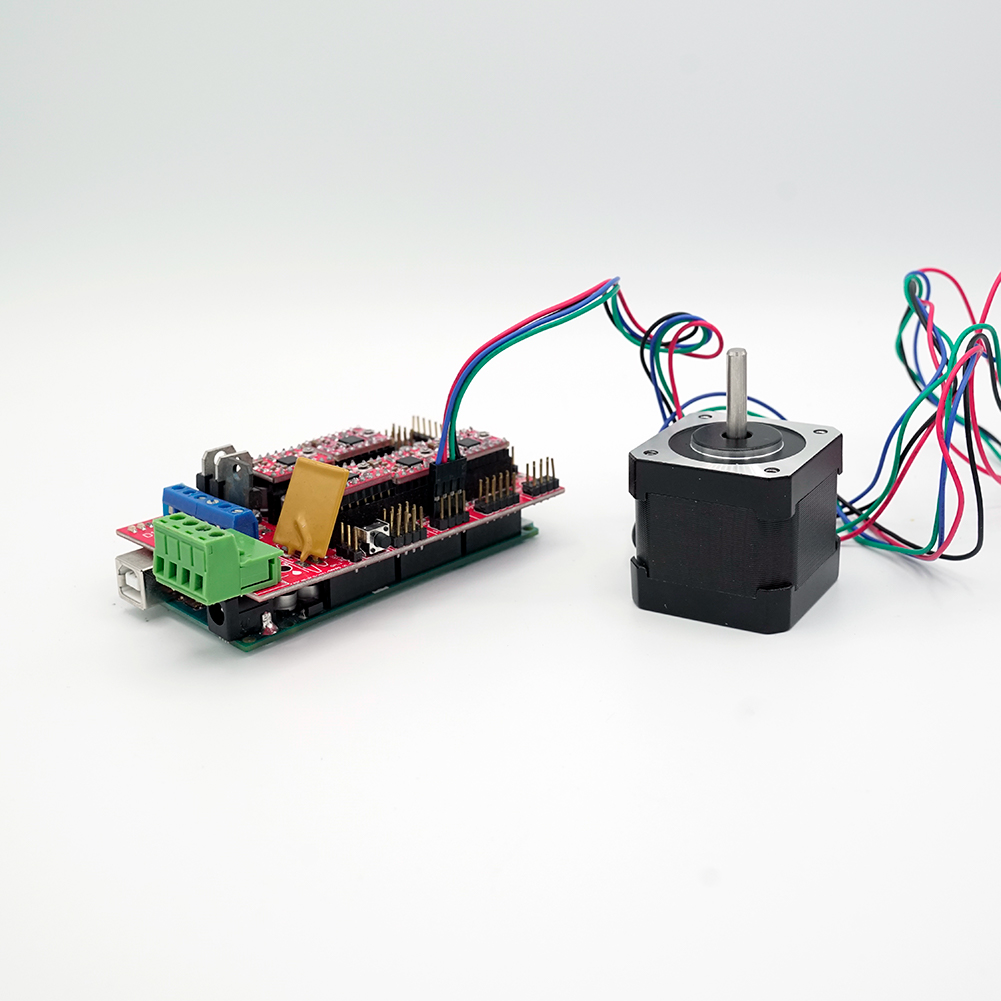

To understand the magic of the stepper motor it is best to briefly talk about its brother, the DC motor. A DC motor converts electrical energy into rotational movement through the attractive and repelling forces of electromagnets. Whenever a DC motor receives power to its terminals its rotor will start to spin. On the other hand, a stepper motor doesn’t spin freely when powered up like a DC motor. It actually takes a coordinated effort by a device known as a stepper driver that sequentially sends varying amounts current known as pulses through the stepper motor’s wires. Each pulse sent to the stepper motor results in a small rotational “step” of the stepper motor’s shaft, hence its name. Each rotational step is a fixed amount and is typically reported in the name of the stepper motor. For example, the shaft of a 1.8 degree stepper motor rotates precisely 1.8 degrees for every step. This 1.8 degree stepper would have to take 200 steps before its shaft completes a full rotation. Expensive positional feedback systems are not necessary for stepper motors because as long as the microcontroller can keep track of how many pulses it has sent to the stepper motor then the total rotational distance is known.

The Next Step: Picking a Stepper

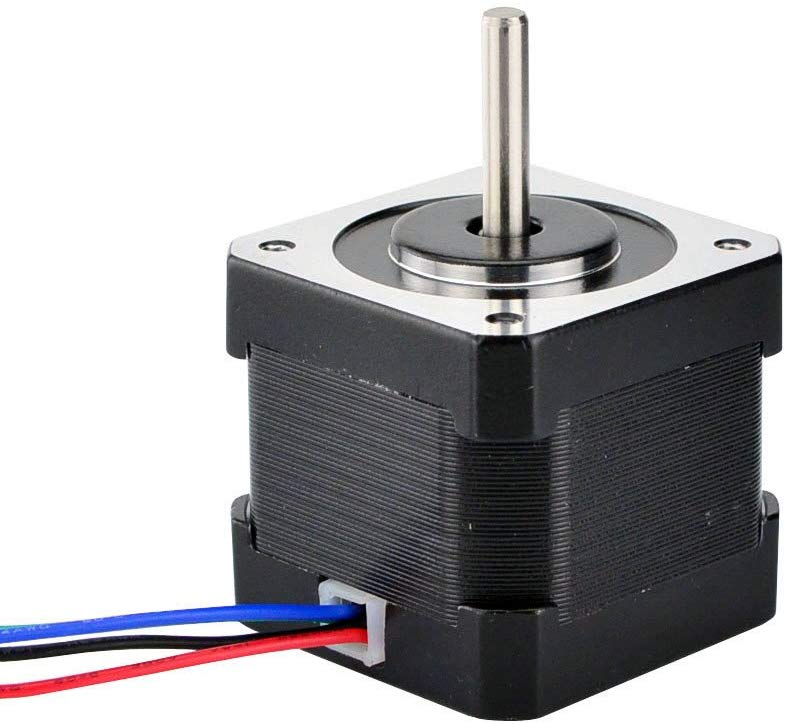

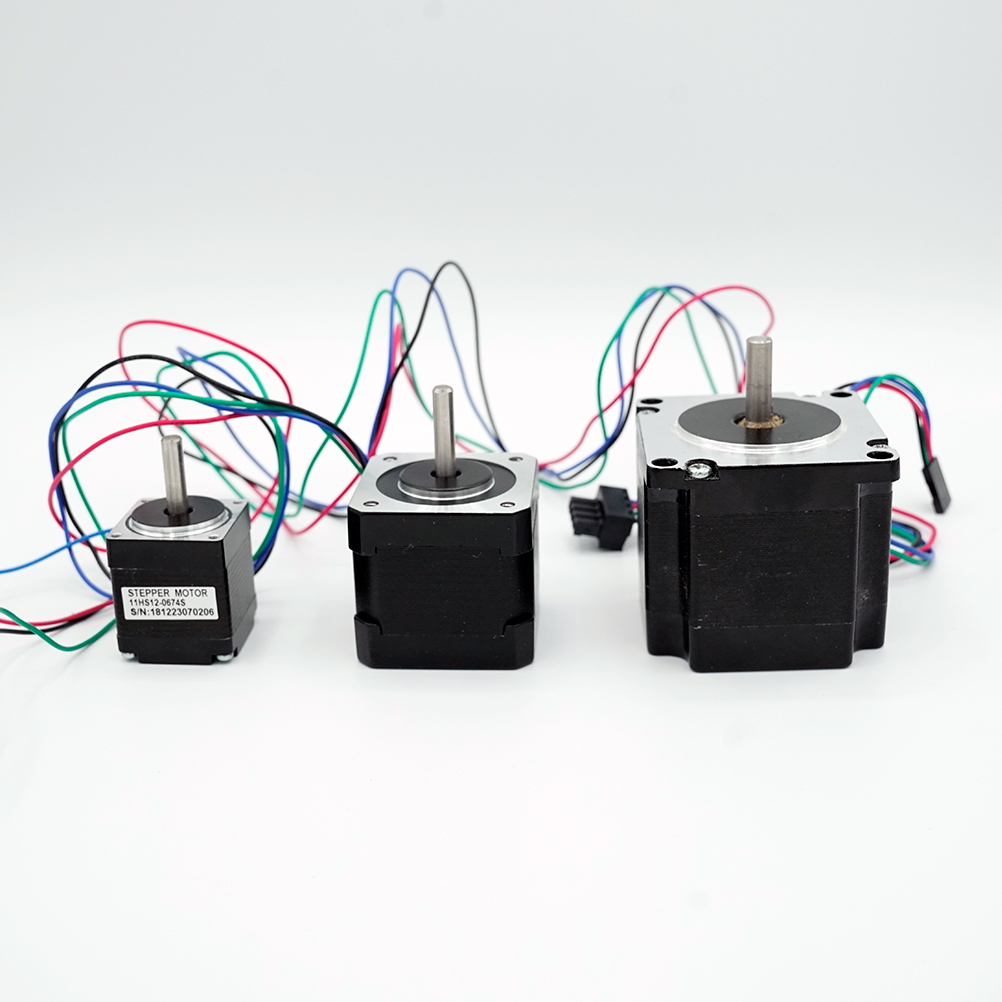

Stepper motors are available in an overwhelming amount of specifications. Fortunately, the National Electrical Manufacturers Association (NEMA) standard has made it much easier to find and purchase motors that will fit your printer’s design. Searching stepper motor on Amazon or Alibaba will return many silver and black stepper motors that have NEMA in the title followed by a number. That number refers to the faceplate size of the stepper motor. For example, a NEMA 17 motor will have a 1.7 inch by 1.7 inch faceplate. Equally as important, all NEMA 17 motors will have the same layout of mounting holes, meaning you can virtually swap out any two stepper motors that fall within the same NEMA. What isn’t specified by the NEMA standard is the depth or length of the stepper motor. Typically, the longer the stepper motor the more torque or turning force that it is capable of. Each NEMA class will come in many different lengths which is why there is such a variety of stepper motor specifications. It’s important to choose a stepper that is powerful enough to drive the linear axes on your 3D printer. However, it is equally as important to not buy steppers that are too large or overpowered for your printer, as these steppers will need significantly more power to operate properly. For a run-of-the-mill 3D printer build, NEMA 17 stepper motors with torque ratings of 60 oz-in are the go to motors.

Gearing

Some stepper motors have extra housing sticking out of their faceplate (see figure 3). This extra metal is known as a gearhead, which contains a series of gears that augment the torque, speed, and step size of the stepper that sits behind it. Geared stepper motors usually sacrifice speed for increased torque and for this reason, are not used on the linear axes of 3D printers where rapid movements are needed. There is, however, an application for geared stepper motors in 3D printing. The process of forcing plastic filament down into the extruder and out of the hot end requires a surprisingly high amount of force at low speeds. Therefore, geared stepper motors are commonly used in the extrusion process, which will be elaborated on further in the extrusion section.

External Resources

There are a lot of different ways to successfully build a 3D printer, many of which are not covered on this website. If you want to learn more about stepper motors, then click through some of the links below to external websites and forums.

Recommended Products

The table below contains parts specific to this section that Dr. D-Flo uses and recommends. Depending on your printer build these parts may or may not be compatible. It is best to use the products below as a launching point to explore similar products on the linked websites. Affiliate links may be present below (depending on the vendor).